Everything you need to know choosing hard PVC sheets

PVC laminates are multi-layered laminate sheets supported by Poly Vinyl Chloride, made by compressing paper and plastic resins under high temperatures. They benefit from a decorative layer on top of raw surfaces like plywood. PVC laminates are corrosion, termites, heat, and water-resistant, making them ideal for kitchen cabinets and counters. PVC laminates are more durable than acrylic, although abrasive cleaners can leave scratches on the surface.

PVC Laminated Boards are a series of finished products, having the structure of various panels as substrates and different decorative sheets as panel surface under the PVC lamination procedures. These laminated boards have the best flatness on the surface and clean & smooth texture on the edges. These products are ideal for bath & kitchen furniture and doors. We are sure of the highest quality and the price competitiveness as well.

The options for PVC foam board laminate are diverse, surface materials are PVC film, high pressure laminate (HPL), aluminum sheet or film, acrylic, PET. The pattern options of surface materials include plain color, wood grain, marble, fabric, etc., and the surface texture options include smooth, frosted, matt, wood grain, slate, leather, etc.

Substrate

Both PVC foam board and WPC foam board are suitable as substrates, and the ideal thickness ranges from 5mm to 30mm. The ideal density is 0.5g/cm3 and above. They can be used directly for lamination, or they can be surface sanded before lamination for a better fit.

Glue

The glue used for lamination is a fixed glue at room temperature, called PUR glue. It is melted into a liquid gel after being heated at high temperature, so that the glue can evenly cover the surface of the substrate.

Decorative Surface Material

There are many options for decorative surface materials. The most common are PVC film, high pressure laminate (HPL), aluminum sheet, in addition to acrylic sheet, PET sheet, and even glass can also be attached to the PVC foam board.

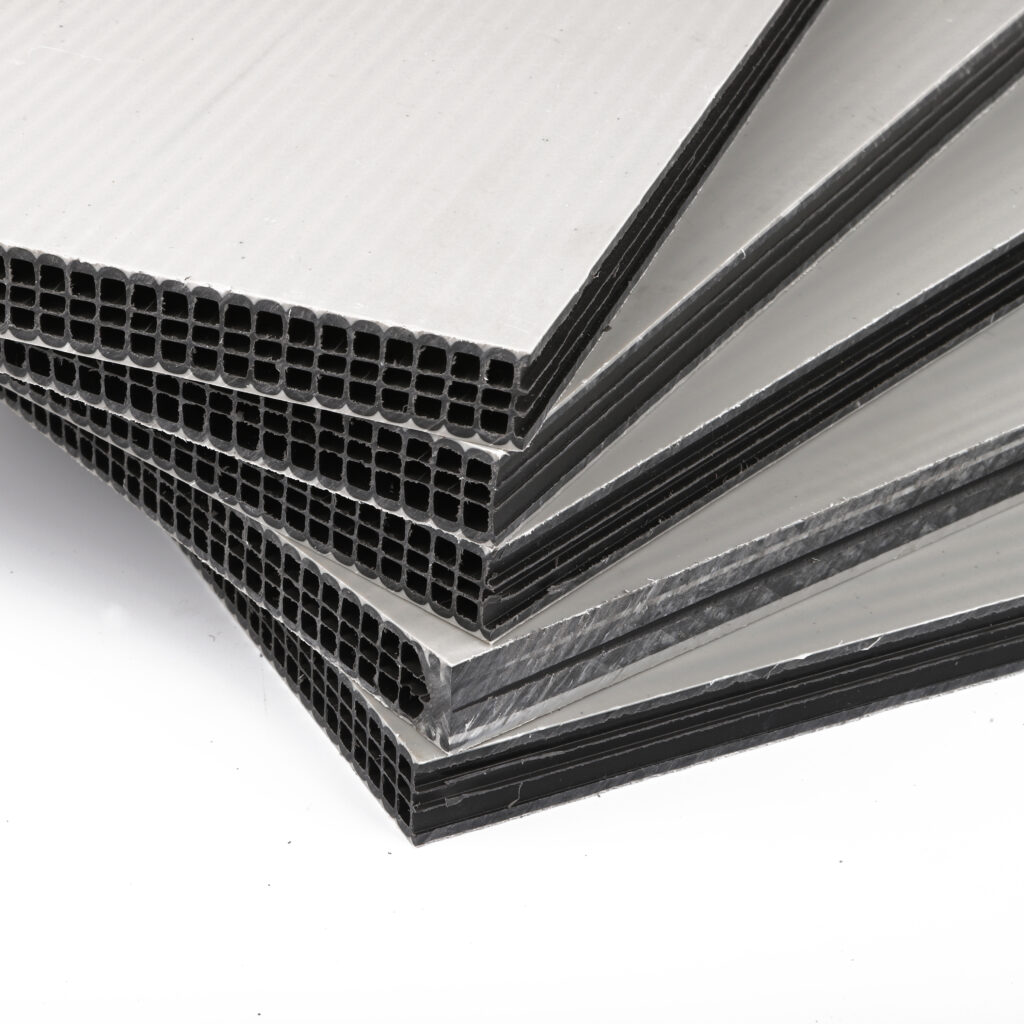

Board Structure

■ High density PVC foam board ( Celuka foam board & WPC foam board) as the substrate

■ Imported PUR hot melt glue as the adhesive

Surface Lamination

■ Laminated Film Options: HPL Sheet, High Glossy Film, Acrylic Sheet, Aluminum Sheet, PVC, Paper, pet film, etc.

■ Adhesive: Adopting Imported High quality adhesive for the bonding; no formaldehyde and benzene elements, strong adhesion of 40-100 N/cm2, safe and eco-friendly.

■ No delamination under the application environment of -40°C – 100°C.

■ Accepting in-house lamination processing on supplied materials or outsourcing materials.

Features:

■ Water-Resistant

■ Anti-Insect

■ Self-Extinguishing

■ Hardness

■ Acoustical Insulation

■ Lightweight

■ Antibacterial

■ Sunlight and UV Resistant

■ Recyclable

Interior Application:

■ Modular kitchen Partitions

■ Wardrobe & Bed

■ Home & Office furniture

■ Bathroom cabinet

■ Ceiling Solution

■ Wall Paneling

■ Hospital Furniture

■ Laboratory Furniture

Exterior Application:

■ Construction

■ Shuttering Boards Exterior Wall Cladding

■ Garden Furniture & Fencing

■ Pre fabricated house

PVC laminating sheet advantages

■ PVC laminate saves the time of the contractors as the same sheet is used for packing the side. There is no need to use edge bands. PVC laminate can be folded up to 90 degrees, which makes it stand out among other options.

■ These laminates are safe for kitchen as they are corrosion resistant, termite resistant, borer resistant, stain resistant, water resistant, lead free, environment friendly, harmful emission free, easy to clean and toxin free.

■ A PVC laminate can be easily cleaned without worrying about the finish as it is waterproof.

■ This sheet comes in many colors and texture and is also highly durable.

■ The installation of PVC laminate is very easy and is done without any tension.

■ One of the attractive features of PVC laminates is that they are economical. You get the look and feel of luxurious items at very reasonable rates.

■ PVC laminates are pre finished, which means there is no need of giving finish before application.