PVC Free Foam Sheets

Everything You Need To Know Choosing PVC Free Foam Sheets

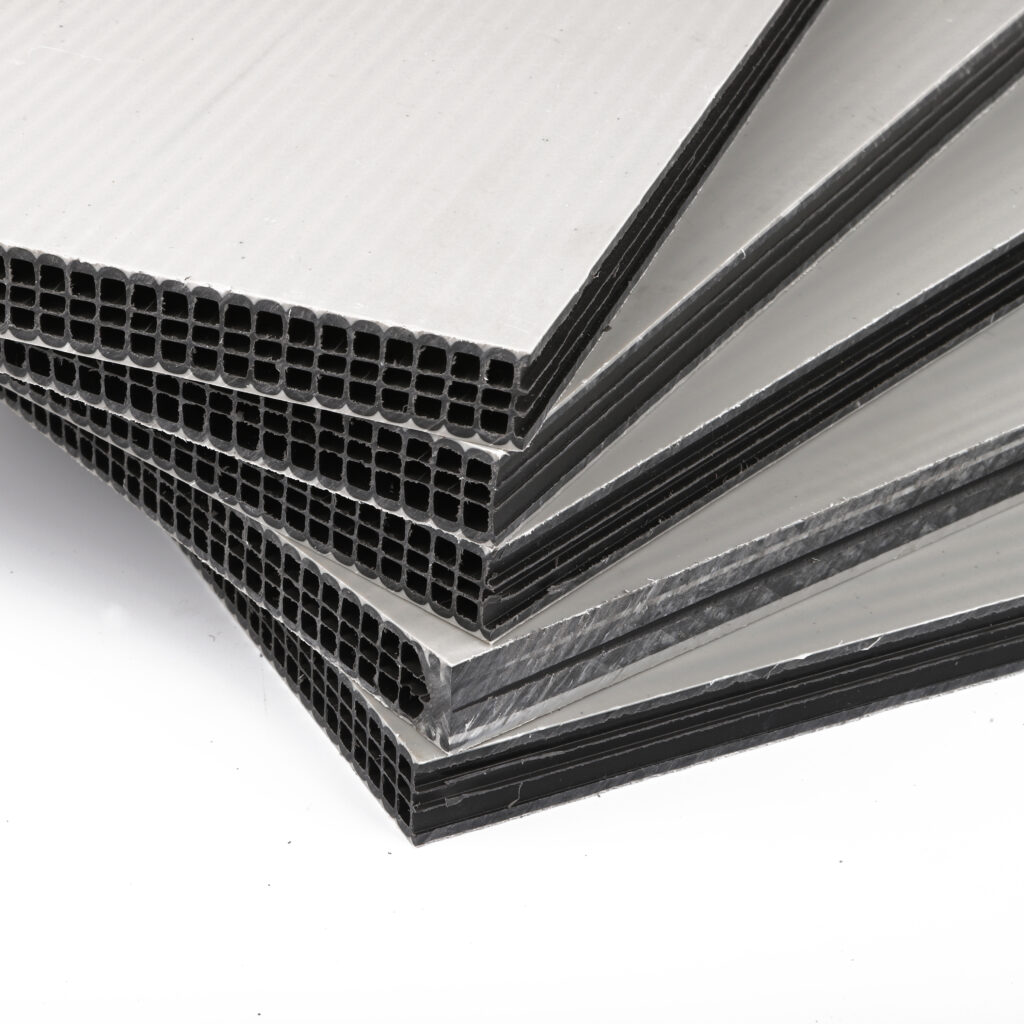

The term “free” refers to the free foam method of its production. The PVC foam melt expands freely as it leaves the die and then enters a calibrator separate from the die. The Free-foam method is the most basic process for producing PVC foam boards (PVC foam sheet). This is why usually PVC free-foam board is the least expensive of all types.

PVC Free Foam Sheet is a chemically foamed, rigid, light weight extruded sheet with fine & homogenous closed cell structure having a smooth matt surface finish on both sides. With several variations, including Expanded PVC also known as PVC Foam. The density of PVC free foam board is low (0.3-0.5). The hardness of the board surface is about 35 shore, and there will be obvious scratches on the nail scraping board. The 1-5mm thin plate is generally used for advertisement mounting display, and the thick plate is mostly used for carving, toy model, billboard advertisement and other purposes.

KINGSTAR Expanded PVC Sheet offers a superior quality, extremely versatile PVC foam sheet that is supplied as a standard with polyethylene masking on one side or without coating on request. The masking film removes cleanly revealing a smooth surface finish ideally suited for screen and digital printing applications.

Features of PVC Free Foam Sheets

Weatherproof and weather resistant

Very good for bonding

Thermoformable

Uniformly and finely structured surface

Simple processing

Uniformly and finely structured surface

Low thermal conductivity

Lightweight

Ideal for punching work

Good surface strength

Flame resistant

Good for laminating

Fine-celled foam structure

Excellent printing quality

Chemical and corrosion resistant

Fine-celled foam structure

Advantages of PVC Free Foam Sheets

1. Lightweight and Durable:

Free foam PVC sheets are renowned for their lightweight nature without compromising on durability. This combination makes them an ideal choice for applications where weight is a critical factor, such as in signage, exhibition displays, and point-of-sale materials. The sheets are easy to handle and transport, making them a preferred choice for various industries.

2. Chemical Resistance:

PVC free foam sheets exhibit excellent chemical resistance, making them suitable for outdoor applications. They can withstand exposure to various weather conditions, including rain, sunlight, and pollutants, without deteriorating. This property extends the lifespan of products made from free foam PVC, making them a reliable choice for outdoor signage and building applications.

3. Versatility in Processing:

The versatility of PVC free foam sheets extends to their ease of processing. They can be cut, shaped, and fabricated into various forms without losing their structural integrity. This flexibility makes them an attractive option for manufacturers looking for materials that can be easily customized to meet specific design requirements.

4. Thermal Insulation:

Free foam PVC sheets offer thermal insulation properties, making them suitable for applications where temperature control is essential. This makes them valuable in the construction industry for applications such as cladding, where thermal insulation is a key consideration.

5. Cost-Effective:

Compared to some alternative materials, PVC free foam sheets are often more cost-effective. This makes them a preferred choice for businesses looking to balance quality and budget in applications like advertising boards, displays, and interior designs.

Applications of PVC Free Foam Sheets

Digital Printing

Dimensional Lettering

Displays

Exhibition and Showroom Stands

Inscription Panels

Photo Lamination

Screen Printing

Shop Window Decorations

Signs

Interior Finishing

Model Building

Shop Design

Traffic Signs for Construction Sites

Processing options

PVC sheets are easy to process. We are happy to explain the various processing options for foamed and hard PVC.

Process foamed PVC (foam sheet)

Foamed PVC can be sawn, cut, drilled, painted and bent. The surface is flat and smooth and can be printed and inscribed very well.

Cutting

Drilling

Sawing

Sawing (jigsaw)

Sawing (circular saw)

Glueing

Bending (warm)

Painting

Nailing

Buy Wholesale PVC Free Foam sheet

Are you on the lookout for high-quality PVC free foam sheets at wholesale prices? KINGSTAR offers an impressive range of chemically foamed PVC sheets that are lightweight, rigid, and boast a fine-textured, closed-cell structure. Our foam sheets provide a smooth surface finish, making them ideal for a variety of applications from construction to advertising and more. Source your PVC foam sheets wholesale today from KINGSTAR and experience the difference quality can make in your projects.