Description

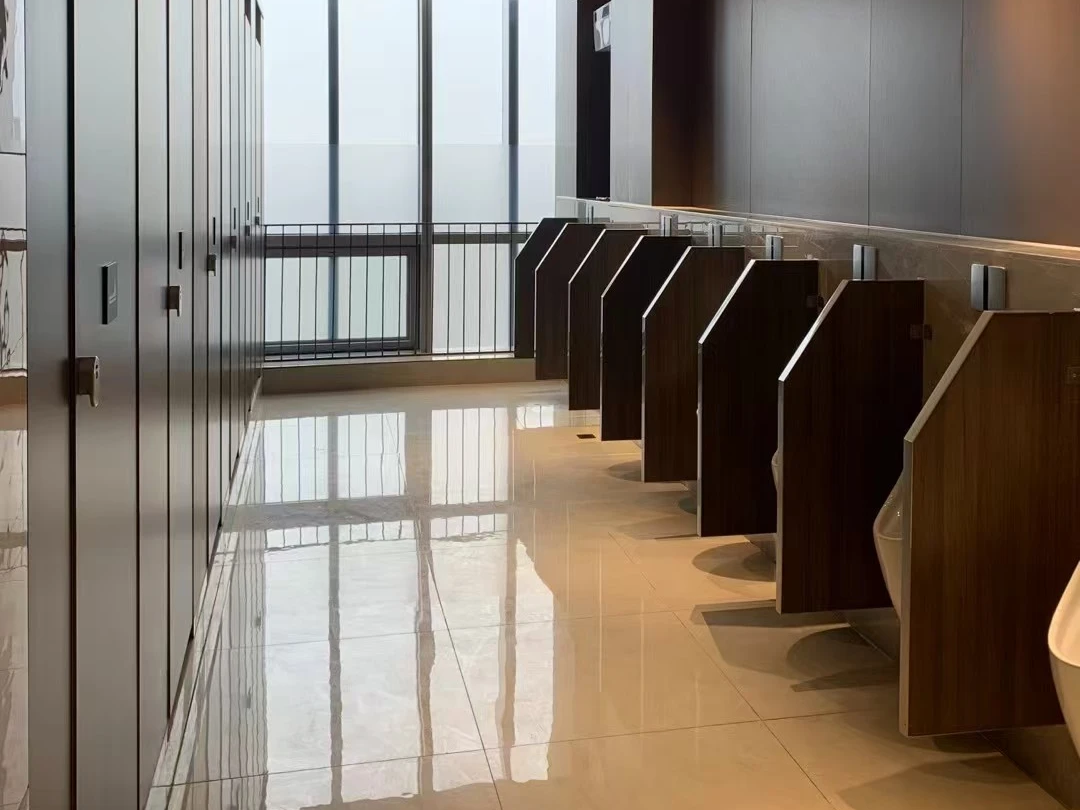

KINGSTAR WPC (wood plastic composite) Celuka foam sheet is a kind of furniture and building material made of PVC and wood powder. It has the same processing method as wood. But compared with the processing performance, it is far superior. Therefore, the WPC foam sheet can be the ideal substitute for wood, aluminum composite board, plywood, MDF, particle board.

Product Range

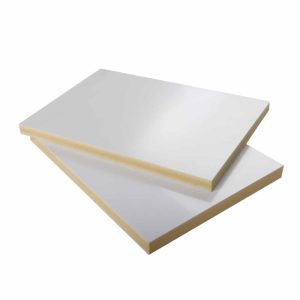

| Product | KS-WPC Celuka Foam Sheet |

| Kind | WPC Foam Sheet |

| Size | 2440*1220mm; 3050*1560mm; 3050*2050mm |

| Thickness | 3-40mm |

| Density | 0.35-0.9g/cm³ |

| Craft | Celuka Foam Extruded |

| Colour | Wooden Yellow |

| Surface | Smooth, Matte, Texture, Embossed, Laminated |

| All dimensions specified are standard dimensions. Other sizes and colours can be customized. | |

Key Features

- Lightweight, Non-toxic

- Dust Proofing, Mildew Resistant, Mothproof

- Waterproof Function, Anti-corrosion

- Impact Resistance, Heat Preservation

- Easy Maintenance & Fabrication

- Environment Protection

- Sound insulation