Description

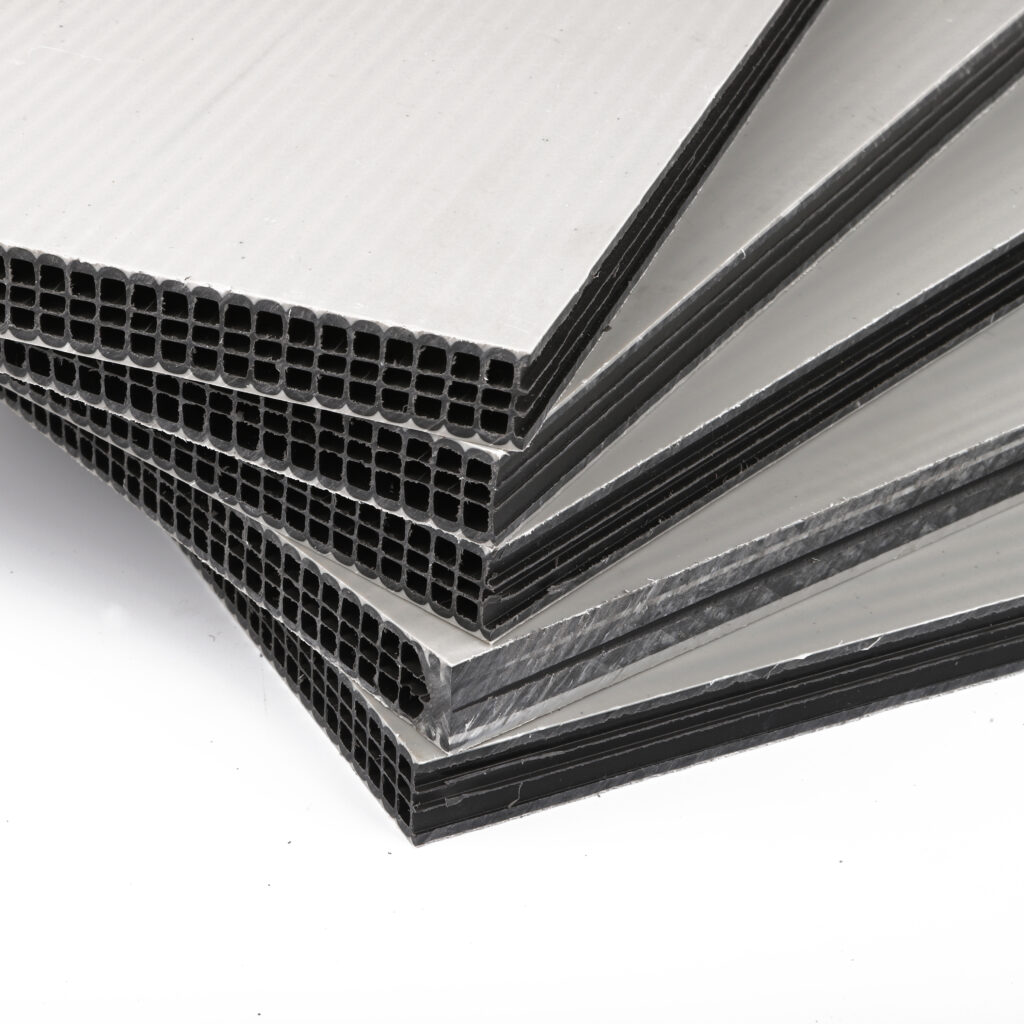

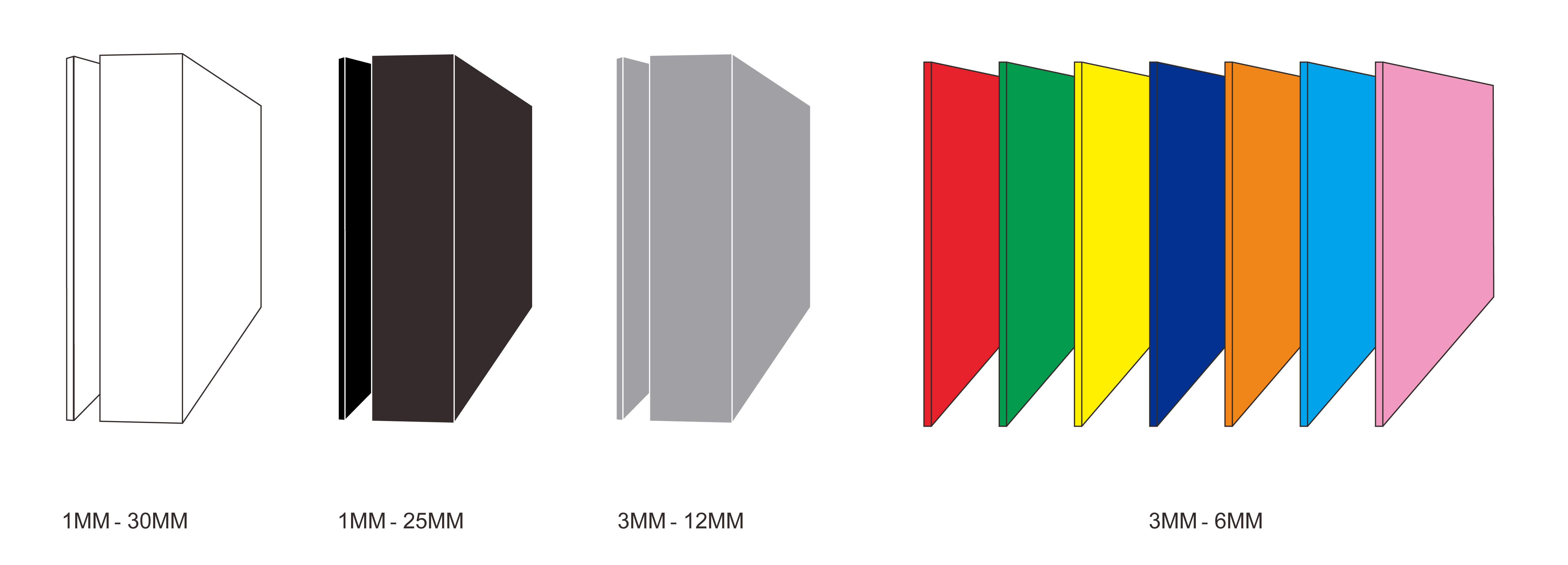

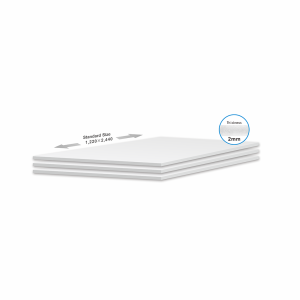

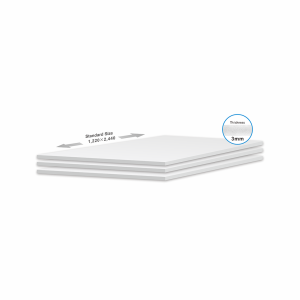

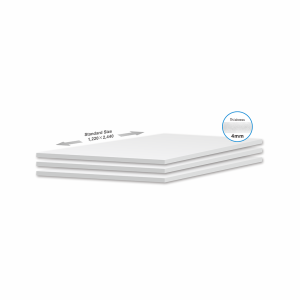

PVC Free Foam Sheet is a chemically foamed, rigid, light weight extruded sheet with fine & homogenous closed cell structure having a smooth matt surface finish on both sides. With several variations, including Expanded PVC also known as PVC Foam. The density of PVC free foam board is low (0.3-0.5). The hardness of the board surface is about 35 shore, and there will be obvious scratches on the nail scraping board. The 1-5mm thin plate is generally used for advertisement mounting display, and the thick plate is mostly used for carving, toy model, billboard advertisement and other purposes.

KINGSTAR Expanded PVC Sheet offers a superior quality, extremely versatile PVC foam sheet that is supplied as a standard with polyethylene masking on one side or without coating on request. The masking film removes cleanly revealing a smooth surface finish ideally suited for screen and digital printing applications.

KINGSTAR PVC Foam Sheet has great characteristics, such as ease of fabrication, that make it perfect for applications in many different industries, including construction, advertising, photographic, electrical, and others.

Our PVC Foam Board Sheet has numerous advantages:

Lightweight and Durable:

Our product offers a lightweight construction combined with exceptional durability, ensuring a long-lasting and reliable solution.

Versatile Applications:

With its versatility, PVC Foam Board finds applications in signage, displays, furniture, construction, and more, making it suitable for a wide range of projects.

Moisture Resistance:

It exhibits excellent moisture resistance, making it ideal for both indoor and outdoor applications that require resistance to water and humidity.

Weather Resistance:

PVC Foam Board Sheet is highly weather-resistant, withstanding exposure to harsh environmental conditions, UV rays, and temperature fluctuations.

Impact Resistance:

Its foam structure provides excellent impact resistance, protecting against potential damage or breakage.

Low Maintenance:

PVC Foam Board Sheet requires minimal maintenance, making it a convenient and cost-effective choice for various applications.

Easy Fabrication:

Our product is easily fabricated, allowing for effortless cutting, shaping, and customization to suit specific project needs.

Fire Retardant:

PVC Foam Board Sheet is available in fire-retardant options, ensuring enhanced safety in applications where fire resistance is required.

Excellent Printability:

PVC Foam Board offers excellent printability, allowing for vibrant and high-quality printing, making it ideal for signage and display applications.

Eco-Friendly Options: It’s available in eco-friendly formulations, promoting sustainable practices and reducing environmental impact.

Outstanding Processing properties

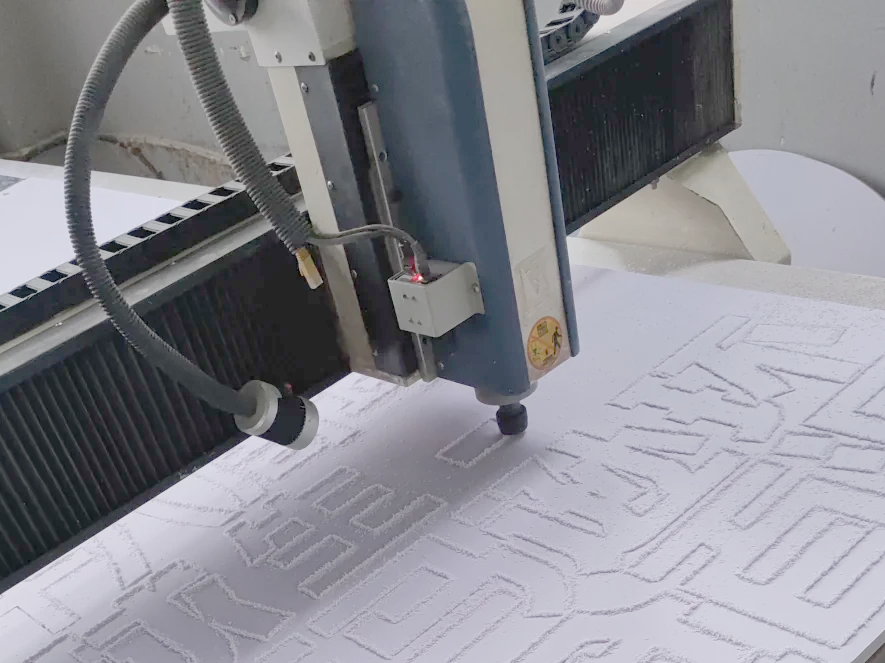

PVC foam board is renowned for its excellent machinability, making it a preferred material for custom fabrication. It supports a wide range of post-processing techniques, including precise cutting, CNC routing and milling, edge profiling, thermoforming, lamination, and printing. Whether for intricate 3D lettering, curved architectural elements, or custom surface finishes, PVC foam board can be efficiently worked using diverse methods to bring creative designs to life, offering a highly adaptable solution for specialized applications.

Cutting

Perfect for DIY projects, thin PVC foam board is exceptionally easy to work with using basic hand tools. Its lightweight and uniform structure allows for clean, precise cuts with simple equipment like utility knives, handsaws, and manual files. This makes it an ideal, user-friendly material for crafters, model makers, and hobbyists.

Nailing

Nailing provides a strong, economical mechanical fastening solution for assembling PVC foam boards. This simple process uses nails or screws to securely join panels, offering high structural reliability and load-bearing capacity without the need for adhesives or specialized tools. It is especially suitable for constructing durable temporary structures, partition walls, exhibition booths, and basic furniture, delivering a fast and cost-effective assembly method.

Screwing

Screw fastening for PVC foam board provides a sturdy and adjustable assembly solution. Using self-tapping screws with pre-drilling prevents material splitting and ensures reliable connections. Washers are recommended to distribute pressure and avoid surface indentation, making this method ideal for displays, furniture, outdoor signage, and other applications that require load-bearing capacity or repeated adjustments—combining installation flexibility with long-term structural stability.

Sawing

Saw cutting offers a fast and precise solution for straight-line or large-format cutting of PVC foam boards. Utilizing a high-speed rotating blade, this process efficiently handles panel sizing, grooving, and trimming, producing clean cuts with sharp edges that typically require minimal post-processing. It is particularly suitable for batch production and large-scale sizing, making it a cost-effective and efficient shaping choice for applications such as architectural partitions, signage substrates, and exhibition stands.

Hinging

Installing hinges on PVC foam board creates durable and functional movable connections. Using embedded installation with reinforced screws and adhesive ensures a flush, stable pivot point ideal for boxes, cabinets, displays, and prototypes. This method combines clean aesthetics with reliable performance for long-term use.

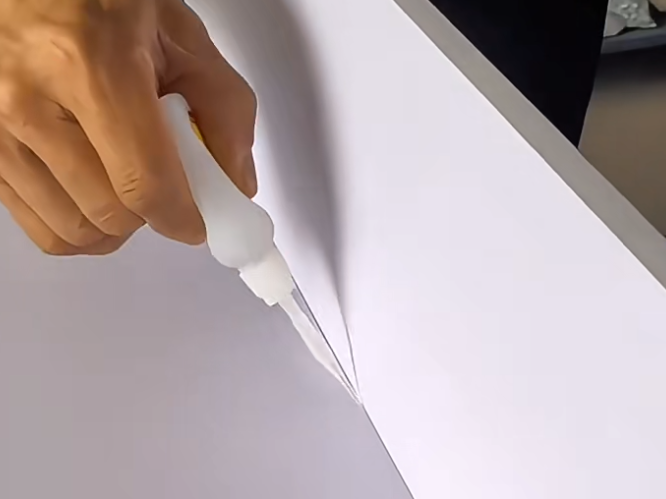

Glueing

PVC foam board offers simple and strong bonding solutions for seamless assembly. Using specialized PVC cement, all-purpose adhesive, or epoxy resin, it enables quick, high-strength bonding with neat and durable seams. The surface is easy to prepare, allowing for seamless splicing, making it widely used in signage, display cases, models, and decorative projects—combining efficiency with long-lasting performance.

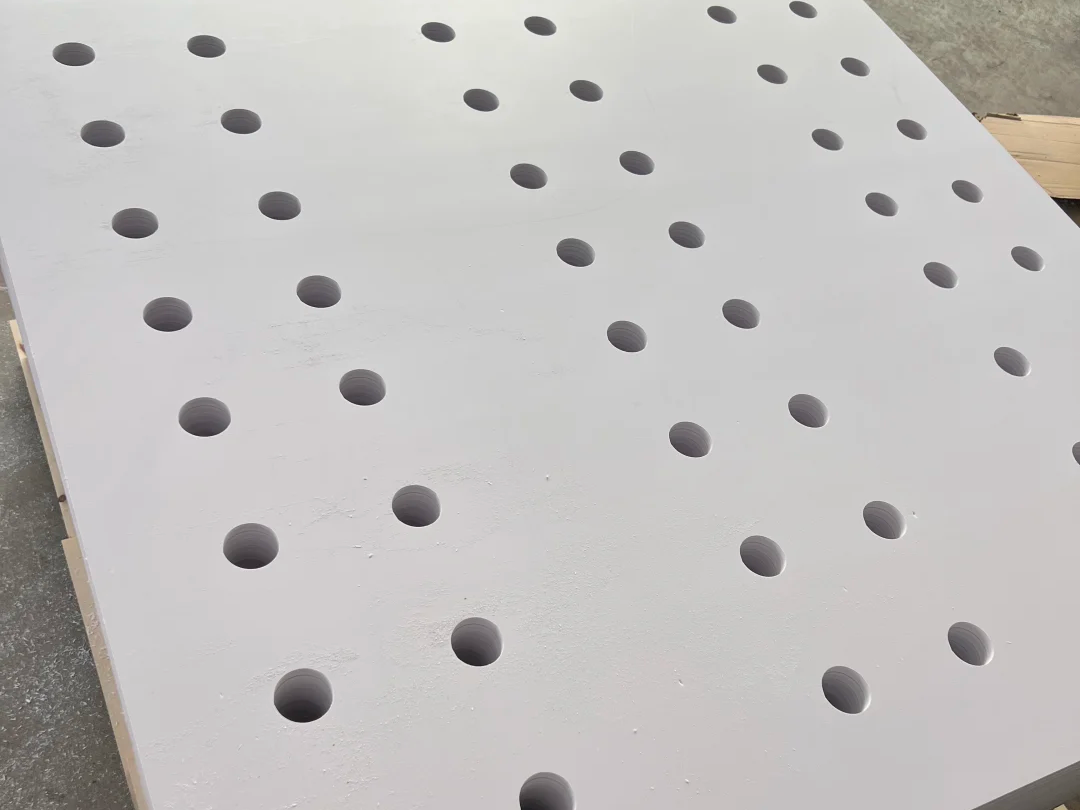

Engraving

PVC foam board offers simple and strong bonding solutions for seamless assembly. Using specialized PVC cement, all-purpose adhesive, or epoxy resin, it enables quick, high-strength bonding with neat and durable seams. The surface is easy to prepare, allowing for seamless splicing, making it widely used in signage, display cases, models, and decorative projects—combining efficiency with long-lasting performance.

Driling

PVC foam board offers simple and strong bonding solutions for seamless assembly. Using specialized PVC cement, all-purpose adhesive, or epoxy resin, it enables quick, high-strength bonding with neat and durable seams. The surface is easy to prepare, allowing for seamless splicing, making it widely used in signage, display cases, models, and decorative projects—combining efficiency with long-lasting performance.

Bending

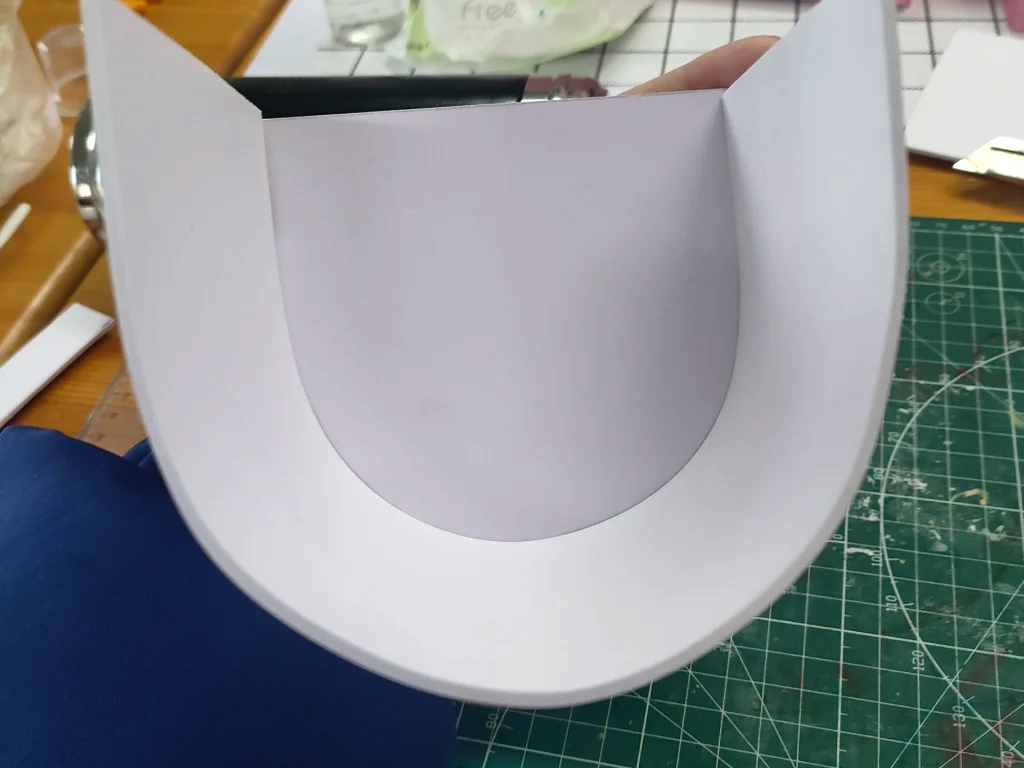

Bending PVC foam board allows for smooth curves and dimensional shapes, primarily through heat bending—softening the material at 70°C–110°C for freehand or mould-assisted forming. Cold bending is used for large-radius arcs, while V-grooving (kerfing) enables precise angled folds. This process leverages the material's thermoplasticity, making it ideal for architectural cladding, exhibition displays, furniture components, and creative designs, offering both flexibility and durable, stable results.

V-grooving

V-grooving (or kerfing) is the key process for achieving precise folds and seamless assembly in PVC foam boards. By cutting V-shaped channels of a specific depth into the back of the board, it allows for easy manual bending to create sharp-edged boxes, displays, signage, and decorative forms. This method eliminates the need for visible seams and additional connectors, combining efficient fabrication with a sleek, integrated appearance.

Screen Printing

Screen printing provides PVC foam boards with durable, high-precision graphics. Through screen/stencil printing, it achieves a solid, vibrant ink layer on the board surface with excellent opacity, making it especially suitable for outdoor signs, advertising displays, and brand logos. This process offers superior weather resistance, cost-effectiveness, and good adaptability to various surfaces (including textured ones).

Baking Paint

The baking paint (or paint-baking) process creates a smooth, high-gloss decorative finish for PVC foam boards. This method involves spray painting followed by high-temperature curing, resulting in a hard, durable, and uniform paint film. It effectively conceals the board's surface texture and offers excellent scratch resistance, corrosion resistance, and UV protection, making it the ideal choice for achieving a modern, premium aesthetic in applications such as architectural decoration, display systems, and furniture.

PVC foam sheet product workshop display

Shipment

We always do our utmost to deliver your package as quickly and neatly as possible. For this reason, we ensure that we package all your orders very carefully and that our shipping rates are fair and transparent.

Carefully packed

To minimise the risk of damage during shipment, we pack your order as effectively as possible. We have developed the optimal packaging method for every material and every size. And if something unexpectedly goes wrong during transport? We will always resolve this immediately.