- Products

- Applications

- Resource Center

TECHNICAL GUIDES & DATA SHEETS

MATERIAL SELECTION TOOLS

- Contact Us

- About Us

Laminated PVC foam sheet is made of PVC foam sheet with double side PVC textured film. Laminated PVC sheet can used for cabinet and furniture making . They are available in various finishes, including matte, glossy, textured, high gloss, and various patterns and plain colours to meet clients’ request on furniture decoration. The PVC film with exquisite color, high saturation and fashionable designs. Wood grain surface is the best seller.

Require Instant Support for Your Specific Needs? Please Send Us a Message!

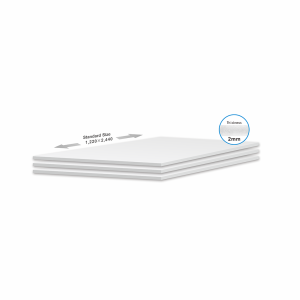

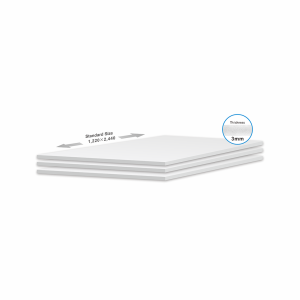

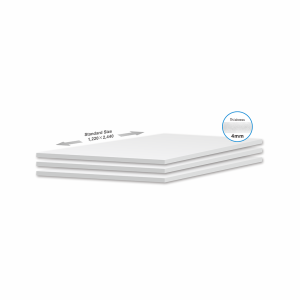

The expanded PVC foam board supplied by Kingstar adopts new technology and new formula to make the product have good flexibility, available thickness from 1mm to 30mm with density 0.4~0.9g/㎤ that can be suited for all purpose. Our premium quality PVC foam board is popular in the Middle East, US and European markets. Over the past years, our products have exported to 70 countries and bring a lot of good reputation to us. Our technical inspectors do fully inspection for each shipment by a qualified standard to ensure the product quality and affirm the loading safety.

Quote plastic, custom projects. Put us to work for you!

Fill out the form below, and we will be in touch shortly.

Let’s get this conversation started. Tell us a bit about yourself, and we’ll get in touch as soon as we can.

Your email address will only be used to respond to your inquiry. The information you submit will be governed by our Privacy Policy