Description

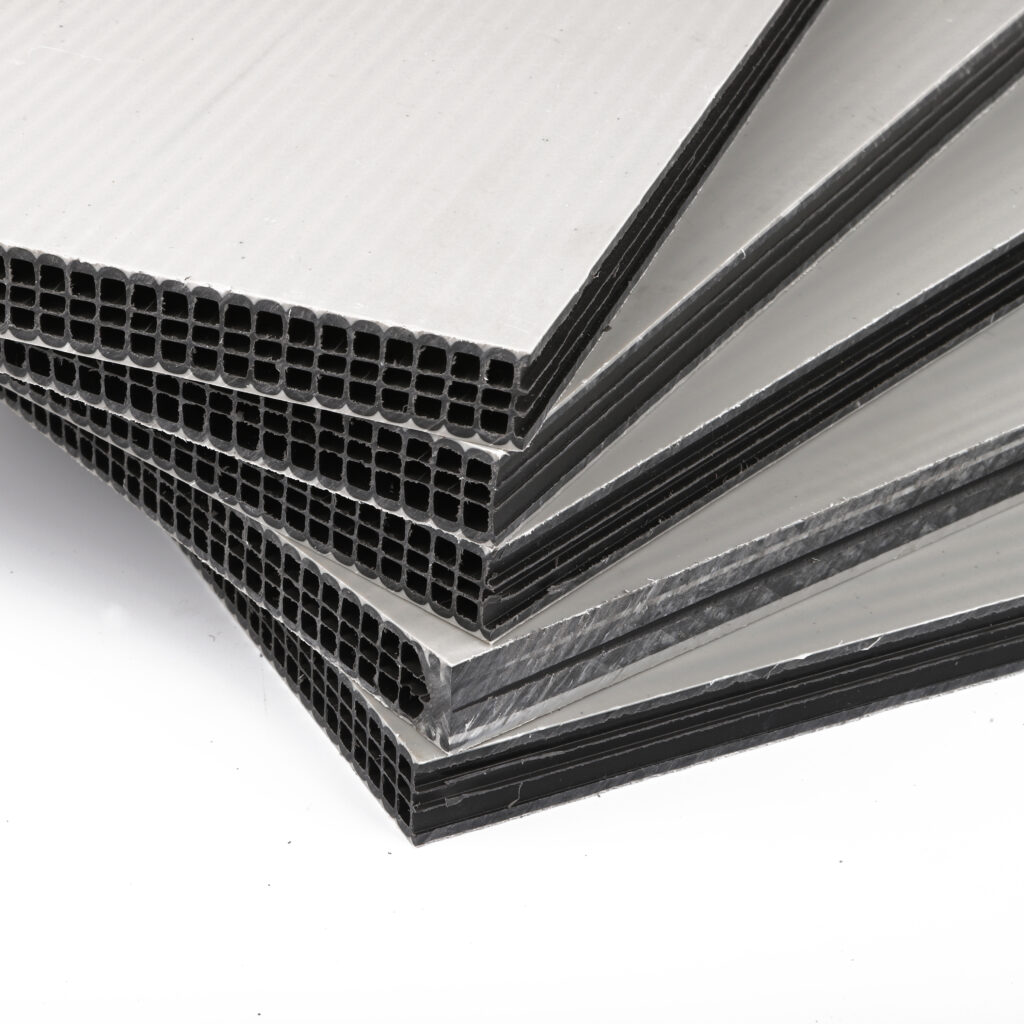

KINGSTAR PVC co-extruded foam sheet are using the co-extrusion process,making it like sandwich panel.The core of the panel is tight and evenly cell foam PVC and 2 sides skins are rigid non-foam PVC.This particular process makes the panel unique performance, provides a hard surface for both thin sheets and thick board. Making it become the good choice for the demanding outdoor, architectural, and industrial applications.

Product Range

| Product | KS-PVC Co-extruded Foam Sheet |

| Kind | PVC Foam Sheet |

| Size | 2440*1220mm; 3050*1560mm; 3050*2050mm |

| Thickness | 3-30mm |

| Density | Core:0.45-0.9g/cm³, Surface:1.2g/cm³ |

| Structure | Rigid PVC+Foam PVC+Rigid PVC |

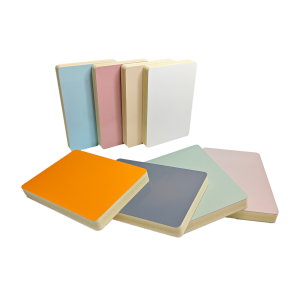

| Colour | White, Black, Grey, Blue, Red, Yellow, Green |

| Surface | High Glossy, Rigid |

| All dimensions specified are standard dimensions. Other sizes and colours can be customized. | |

Key Features

- Solid PVC surface skin

- High-gloss & non-porous finish

- Extreme impact resistance

- Superior weather and UV resistance

- Excellent chemical resistance

- Easy to clean and maintain

- Moisture resistant and impermeable

- Sound and vibration absorbent

Difference between Celuka and Co-extruded

| Feature | Co-extruded Foam Board | Celuka Foam Board |

| Manufacturing Process | Multi-layer extrusion (solid outer skin + foam core) | Controlled expansion (microcellular foam with smooth, hard outer surface) |

| Surface | Smooth and high glossy | Smooth with matte look |

| Strength | Strong impact resistance | Sturdy but with better toughness |