Description

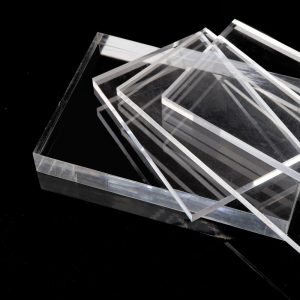

KINGSTAR extruded acrylic sheet is produced through a continuous, high-efficiency manufacturing process where acrylic pellets are melted and forced through a precision die, then shaped and cooled between polished rollers. This method balances performance, versatility, and cost-effectiveness, making extruded acrylic a popular choice for a wide range of commercial and industrial applications.

Product Range

| Material | PMMA |

| Size | 2440 * 1220mm, 1830 * 1220mm, 3050 * 2050mm |

| Thickness | 0.5-12mm |

| Density | 1.2g/cm³ |

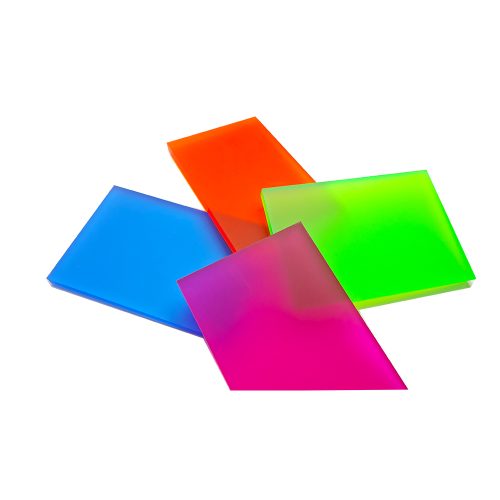

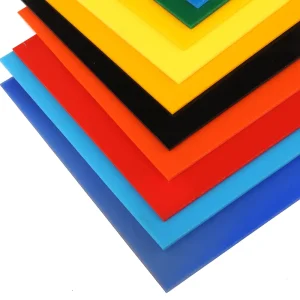

| Color | Clear Transparent, Solid Color, Glittering |

| Surface | High-glossy, Matte, Embossed, Mirror |

| All dimensions specified are standard dimensions. Contact us to get your customized sizes and colors. | |

Key Features:

- Uniform Thickness & Consistency: Highly consistent thickness across large sheets or continuous rolls, ideal for volume production.

- Cost-Effective Production: Lower manufacturing costs compared to cast acrylic, offering a budget-friendly option for large-scale projects.

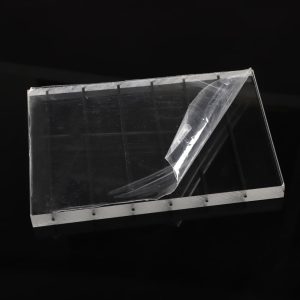

- Excellent Thermoforming Capability: Softens evenly at lower temperatures, making it easier to heat and shape into curves, angles, or custom forms.

- Wide Range of Textures & Finishes: Easily embossed, patterned, or finished with surfaces like matte, glossy, mirrored, or structured textures during production.

- Good Optical Clarity & Light Transmission: Provides high transparency (up to 92% light transmission) with reliable visual quality for most applications.

Quick Comparison

| Aspect | Cast Acrylic Sheet | Extruded Acrylic Sheet |

| Clarity & Gloss | Excellent | Very Good |

| Impact Strength | Higher | Slightly Lower |

| Chemical Resistance | Superior | Good |

| Cost | Higher | More Economical |

| Best For | Precision, durability, aesthetics | Volume production, textured finishes |