Description

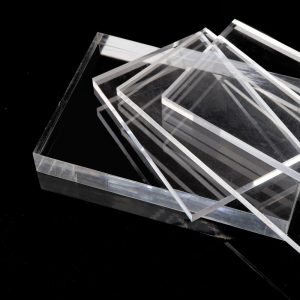

KINGSTAR cast acrylic sheet is manufactured through a precision casting process, in which liquid acrylic monomer is poured between two polished glass or metal plates and then slowly cured in a temperature-controlled oven. Casting process produces sheets with exceptional optical and mechanical properties, making cast acrylic a premium material for high-performance applications.

Product Range

| Material | PMMA |

| Size | 2440 * 1220mm, 1830 * 1220mm, 3050 * 2050mm |

| Thickness | 2-60mm |

| Density | 1.2g/cm³ |

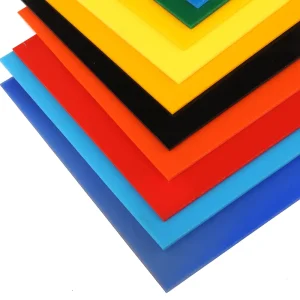

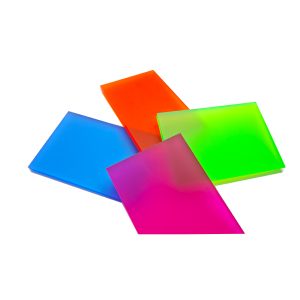

| Color | Clear Transparent, Color Transparent,Solid Color |

| Surface | High-glossy, Matte |

| All dimensions specified are standard dimensions. Contact us to get your customized sizes and colors. | |

Key Features:

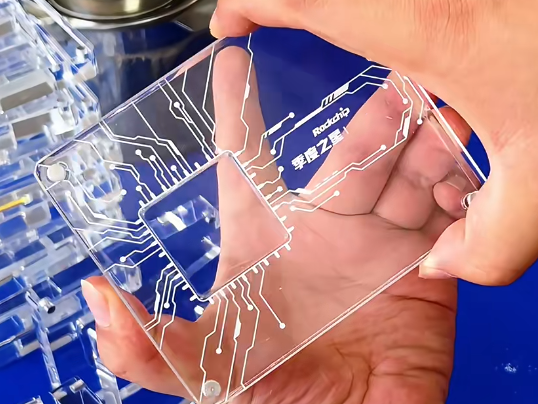

- Superior Optical Clarity & Brilliance: Offers glass-like transparency with minimal distortion, ideal for displays and lenses.

- High Impact Strength & Durability: More resistant to cracking and breaking compared to extruded acrylic and standard glass.

- Excellent Chemical & Weather Resistance: ithstands exposure to solvents, cleaning agents, and outdoor UV radiation without yellowing.

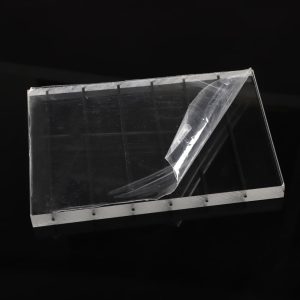

- Outstanding Thermoforming Ability: Can be heated and shaped into complex curves and deep-drawn forms without losing clarity.