Description

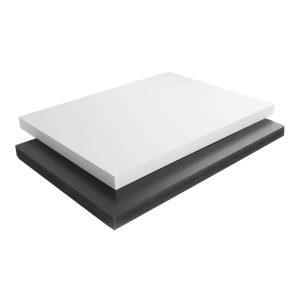

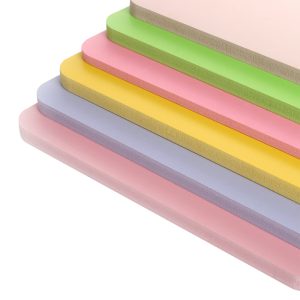

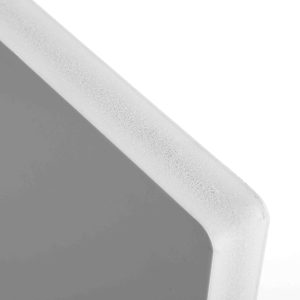

KINGSTAR PVC Celuka foam sheet, is a high-performance panel engineered through an advanced celuka (skin-forming) foaming process. It features a rigid, non-porous PVC skin fused to a lightweight, fine-celled foam core. This unique “solid skin + foamed core” structure delivers the superior strength and durability of solid plastic with the easy workability and lightness of wood, making it the premier choice for high-end signage, architectural interiors, and furniture & cabinet making.

Product Range

| Product | KS-PVC Celuka Foam Sheet |

| Kind | PVC Foam Sheet |

| Size | 2440*1220mm; 3050*1560mm; 3050*2050mm |

| Thickness | 2-30mm |

| Density | 0.3-0.9g/cm³ |

| Craft | Celuka Foam Extruded |

| Colour | White, Black, Grey, Blue, Red, Yellow, Green |

| Surface | Glossy, Matte, Texture, Embossed, Laminated |

| All dimensions specified are standard dimensions. Other sizes and colours can be customized. | |

Tolerence

| Range

(based on thickness) |

Thickness | Length | Width | Rectangularity |

| ≤10 | Within +0.2mm | Within +5mm | Within +3mm | Within +3mm |

| >10 | Within +0.5mm |

Key Features

- High Surface Hardness & Scratch Resistance

- Excellent Impact Strength & Durability

- Waterproof & Moisture-Resistant

- Lightweight & Easy to Handle

- Superior Surface Smoothness for Printing

Outstanding Processing properties

Designed for versatility across advertising displays, furniture, wall panels, and cabinets, PVC Celuka foam sheet offers excellent workability and a smooth surface for a variety of finishing methods. The following fabrication processes are tailored to leverage its adaptability and visual appeal in both interior and lightweight applications.

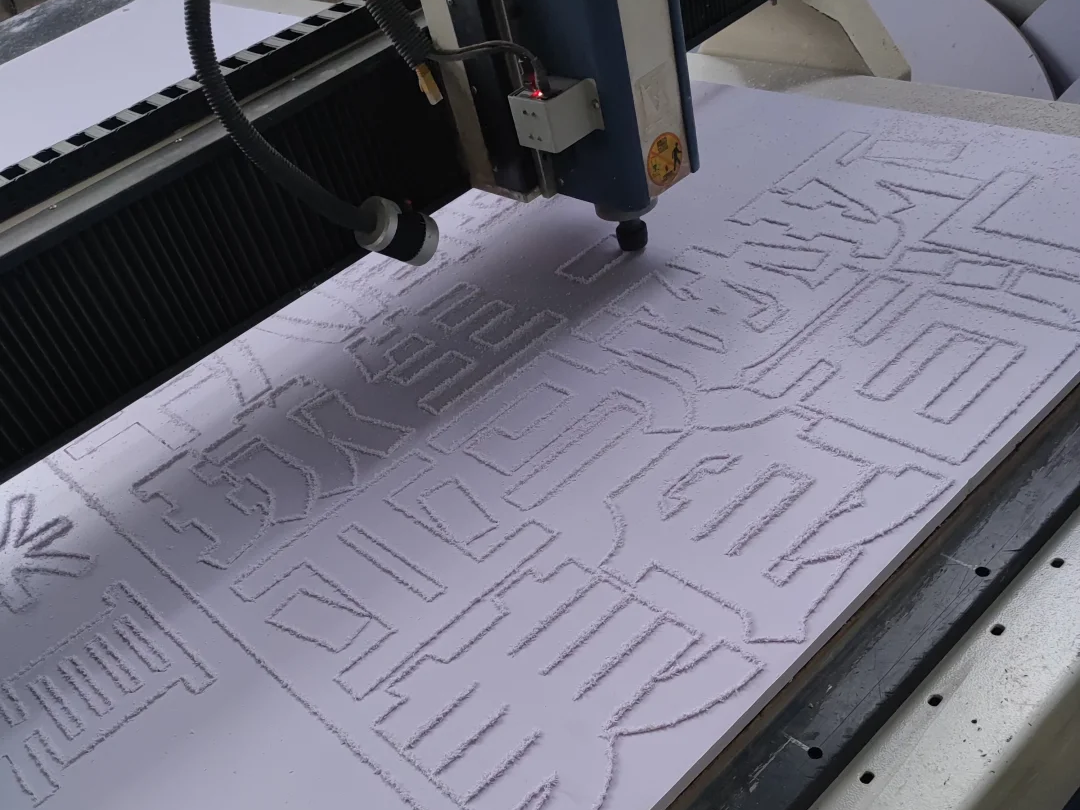

CNC Router

PVC Celuka foam sheet can be precisely cut, routed, and engraved using CNC equipment to create detailed shapes and custom components for cabinets, signage, and furniture.

Screwing & Nailing

PVC Celuka foam sheet supports direct screw and nail fastening for structural assembly, commonly used in cabinet backing, furniture frames, and display fixtures.

Edge Banding

The edges of PVC Celuka foam sheet can be finished with matching or contrasting edge banding for a clean and durable look in cabinet and furniture applications.

Lamination

Decorative films or veneers can be laminated onto PVC Celuka foam sheet to enhance its appearance and resistance, making it ideal for furniture surfaces and interior wall panels.

Hinging

Hinges can be securely installed on PVC Celuka foam sheet using integrated inserts or reinforced mounting points, enabling durable door and cabinet construction.

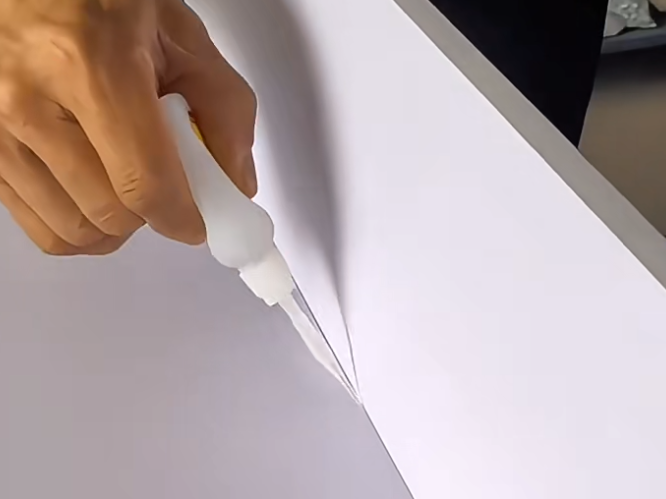

Glueing

For thinner PVC Celuka foam sheets, they can be reliably joined and assembled using compatible high-strength adhesives, offering seamless bonds for layered structures or decorative inlays.

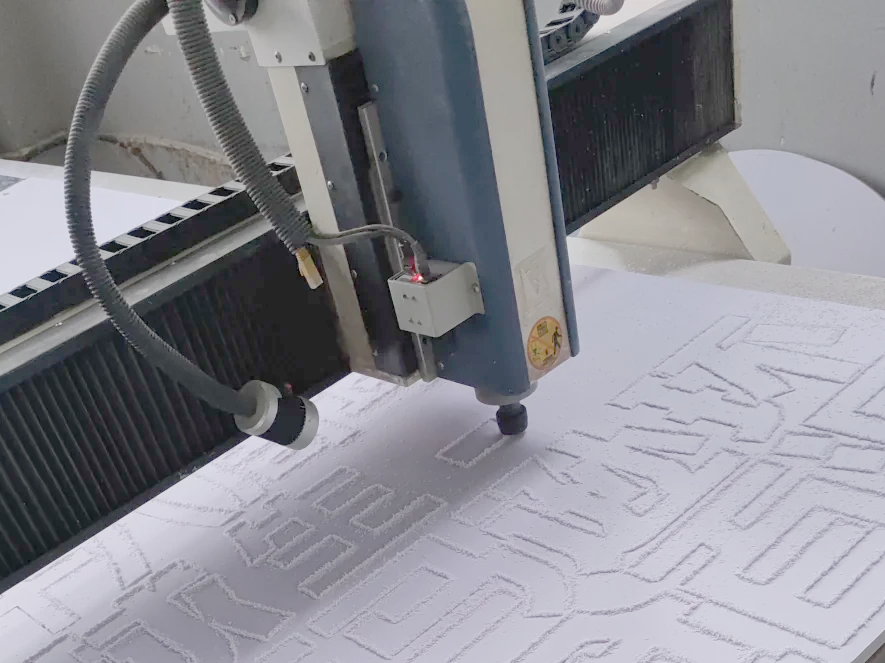

Engraving

Surface details, textures, or decorative patterns can be cleanly engraved into PVC Celuka foam sheet, adding branding or design elements without cutting through the material.

Thermoforming

By applying heat, PVC Celuka foam sheet can be formed into curved or three-dimensional parts suitable for decorative wall panels and furniture elements.s, and creative designs, offering both flexibility and durable, stable results.

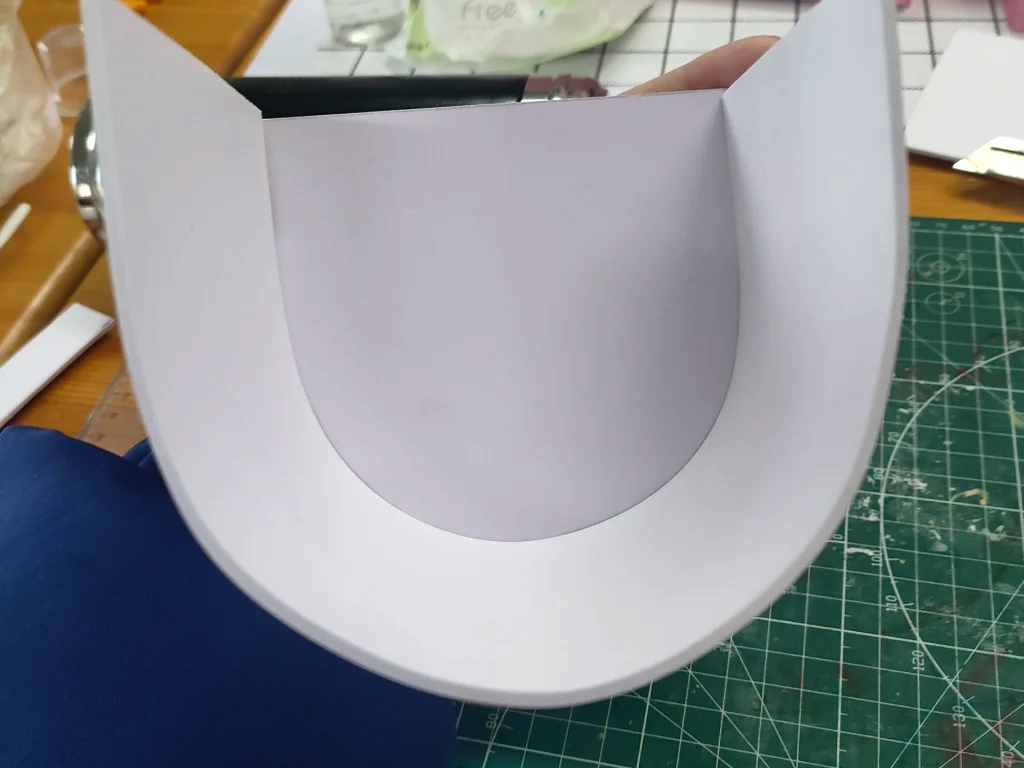

V-grooving

Shallow V-shaped grooves are cut into the back of PVC Celuka foam sheet, allowing the material to be cleanly folded for creating multi-sided display stands or enclosures without separate joints.

Screen Printing

Simple logos, text, or solid-color designs can be applied to PVC Celuka foam sheet through screen printing, ideal for mass producing branded signs and displays.

Tongue and Groove

Precise slots can be cut into PVC Co-extruded foam sheet to insert panels, conceal wiring, or seamlessly join two sheets edge-to-edge, creating a flat, seamless surface for high-end displays and furniture.

PVC foam sheet product workshop display

Shipment

We always do our utmost to deliver your package as quickly and neatly as possible. For this reason, we ensure that we package all your orders very carefully and that our shipping rates are fair and transparent.

Carefully packed

To minimise the risk of damage during shipment, we pack your order as effectively as possible. We have developed the optimal packaging method for every material and every size. And if something unexpectedly goes wrong during transport? We will always resolve this immediately.