Everything you need to know about choosing PP Hollow Construction Formwork

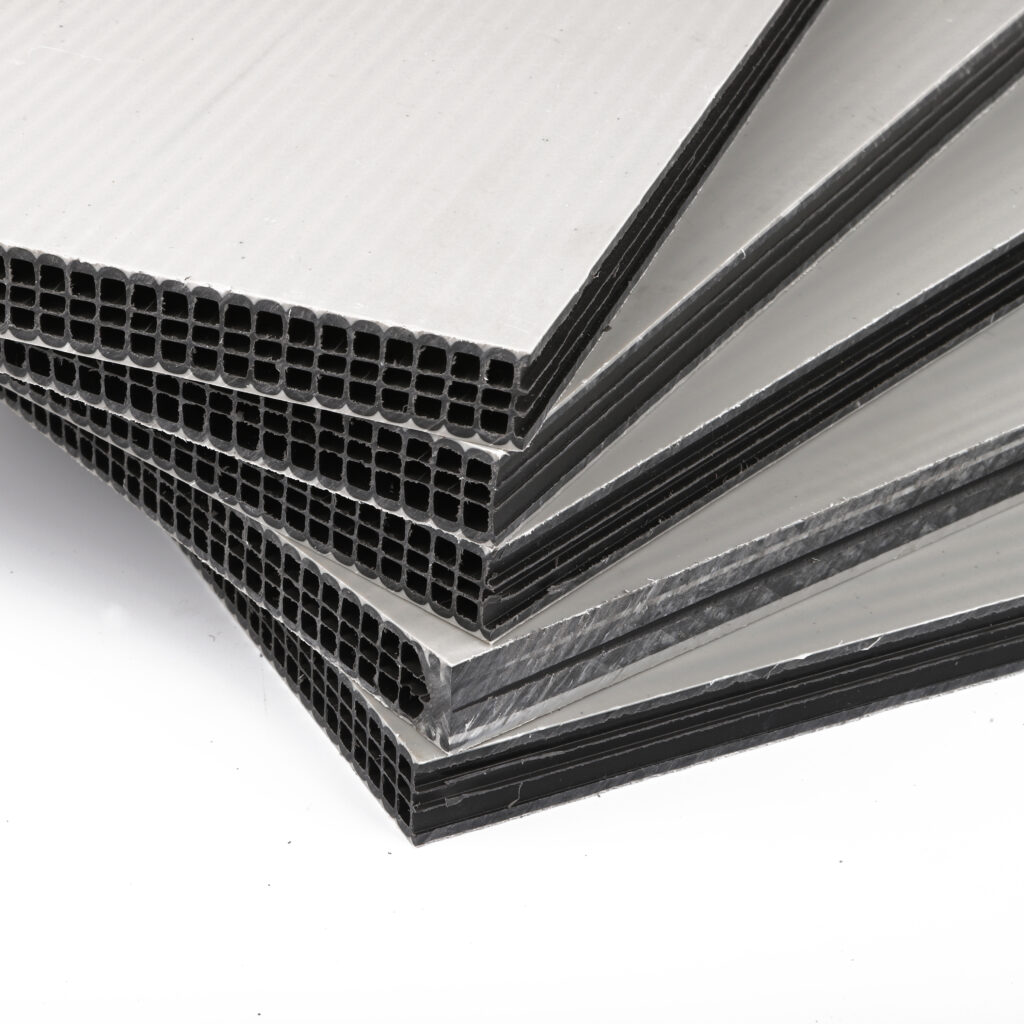

PP hollow formwork also called Plastic Construction Formwork is made of modified PP powder with other additives by heating and extruding. It has high reuse times and water proof can replace traditional plywood. Eco friendly and easy to assemble. It is a style of building concrete structures with reusable plastic molds. This method requires almost no labor skills, gets the job done in record time, with minimal wastage in the process.

PP hollow construction formwork is resistant to water and heat, which makes it strong and light compared to wood or metal. We can meet the thickness or strength of you for your specific situation. PP hollow formwork is specially processed on surface. This kind of formwork has a stronger & smooth surface, it can be easily released and it can bear higher temperatures like above 45°C for the recycling process. PP Hollow Construction Formwork can be kept stable and smooth in hot weather and seasons. It has no absorption of moisture, no deformation, no mildew. So, you can easily count on them to use in different environments and underground.

Advantage of PP Hollow Construction Formwork

■ Reuse More Than 60 Times

■ Waterproof

■ No Need Oil, Easily Install And Remove Only Tapping Formwork Can Be Felled Off

■ No Expansion, No Shrinkage, High Strength

■ Bearable Temperature:-10-70ºC

■ Anti-Slip

■ Shorten Construction Period

■ Glass Glue Can Repair Scratch On The Surface

■ Plastic Plug Can Repair The12-24mmmdiameter Hole

■ Rinse With Water Will Be Clean

■ Rent And Reuse Another Construction Site

■ Recycle At About Half Price In Any Other Plastic Factory

■ Higher hardness: hardness can reach 70 shore D

■ Stronger impact resistance

■ Stronger nail capacity

■ High toughness

Basic Installation Requirements of PP Hollow Construction Formwork

■ The joints of the formwork should be tight and flat without misalignment.

■ The joints of the formwork should be on the wood/steel frame. If there are gaps, tape should be used to seal them.

■ The hole direction of the hollow plastic formwork should be perpendicular to the horizontal plane, and the hole should be sealed with adhesive tape to prevent the cement slurry from seeping into the hole.

■ The connection between the hollow plastic formwork and the wood/steel frame should be firm, and no relative displacement should occur during construction.

Plastic formwork VS Traditional formwork

Item | Hollow Plastic Formwork | PVC Formwork | Wooden Formwork | Aluminium Formwork |

Price(USD) | 12.53 | 11.24 | 5.25 | 119.94 |

Available times | 50 | 20 | 6 | 100 |

Drop test(10m) | No break | No break | break | Severe deformation |

Abrasion resistance | Excellent | Excellent | Bad | Excellent |

Deformation condition | No deformation | No deformation | Deformation | No deformation |

Stripping process | Easy | Easy | Difficult | Difficult |

Book nail | Easy | Difficult | Easy | No nails |

Dilatability and shrinkage | Very little | Variation with temperature | Little | Little |

Energy-saving | Recycled | Recycled | Large lumber consumption | Recycled |

Weight(kg/㎡) | 7 | 13 | 7.2 | 25 |

Scrap value(USD/㎡) | 4.20 | 2.70 | 0.15 | 29.99 |

Share cost(USD) | 0.17 | 0.42 | 0.84 | 0.90 |

Specification of PP Hollow Construction Formwork

Color: Grey, black, yellow, green and so on.

Thickness(mm) | Size(mm) | Weight(kg) |

15 | 915*1830 | 14-15 |

16 | 915*1830 | 15-16 |

17 | 915*1830 | 16-17 |

18 | 915*1830 | 17-18 |

15 | 1220*2440 | 24-25 |

16 | 1220*2440 | 26-27 |

17 | 1220*2440 | 27-28 |

18 | 1220*2440 | 29-30 |

All raw materials for each sheet are produced using new materials from Sinopec Corp., and do not contain any recycled raw materials. In -10℃-40℃ temperature weather, the expansion of the sheet is <1mm. | ||